I was finally able to throw the switch a couple days ago on the new system and after a few hiccups with the VOController I can report all is good. I shot a bunch of video during the install so if i ever get the time I hope to upload my install experience.

I started the install on Labor Day and between family time, resting from the work week, and the swine flu I managed to install the system in stages and still drive the car as needed. First I did the plumbing, then the fuel lines (not fun depending on a 4.5g fuel tank, but I don't drive far to work most days) and finally the electric.

I feel this system is more robust then my previous system and is based on my expreience with  the original KungPaoJetta. In the end it was a self assembled system that worked best for me - the best parts from different kit makers.

the original KungPaoJetta. In the end it was a self assembled system that worked best for me - the best parts from different kit makers.

Before I threw the switch with 92,300 miles I made sure to get an oil report. This provides some idea of the state of the engine before the conversion. I do have some concerns about the report but at least I know the issues with the iron and the concern that the oil looks older then it is are not caused by the conversion. This is something I need to pay attention to with the next report. The engine oil was changed before I threw the switch. The car sat for several months after purchase and the engine oil is over a year old. Here is a view of the engine bay as of today. You can see much but you get an idea of the general lay out of things. As I said I hope to add more information as I have time.

Here is a view of the engine bay as of today. You can see much but you get an idea of the general lay out of things. As I said I hope to add more information as I have time.

Because of my short drives to work and the time it takes for oil to get hot I do not anticipate switching to vegetable oil that often. This is due to the damage that can occur to the engine if oil is injected into a cold engine. Anyone who has read this plug and/or done their homework knows this is a big concern for anyone who plans on going the WVO route and preserving the life of their engine.

Sunday, November 01, 2009

Finally

Sunday, July 19, 2009

Stuck valve

As I was about to move onto the fuel portion of my install when I noticed that one of my HydraForce Valves wasn't making the "clicking" sound it usually makes for the on/off action. After further review I noticed that the other 2 were not functioning either. Basically they are stick from sitting for 6 months with SVO in them

Currently the plumbing (coolant) on the car is finished and I am driving it normally. I thought I would ask over on the Biodiesel & SVO forums ask if they can be cleaned and if so how. I tried glycerin, PB Blaster & Purple Power with no luck.

Mr. Anderson who I respect quite a bit recently posted a video demonstrating flow rates and more importantly that the Hydraforce valves can leak(the leaking is in the 2nd video)

I don't visit the forums very often but I'm glad I stumbled upon this because I could have installed my valves and had this problem. It also shows how one needs to be on top of the changes and corrections that are being made. Unfortuantely the thread has deteriorated into a war of words

Although Mr. Anderson's valves are expensive ($160+ each)I will want the piece of mind and will have to wait till I get the new valves before I can continue with my install. Someone in the post mentioned Omar's valves he is selling on eBay but I like the idea of a metal housing.

Monday, June 29, 2009

Laying the parts out

I shot a little video laying everything out. I didn't go into much detail about things - I forgot to mention most importantly that you should get a manual of some type. I did my first install with the Haynes manual pictured right but have since purchased the Bentley Publishing full blown service manual ($100), other then confirming the coolant flow direction I haven't really needed the Bentley version. Just make sure you get the right manual.

Sunday, June 28, 2009

Prep, Prep, Prep . . . & more Prep

I'm very close to starting the install of my SVO system on my '02 Jetta TDI wagon version 2.0. I've had a few things going on so it's been hard to set aside the time (and lack of car) to get started. Looks as though this upcoming week will provide the opportunity. Hopefully 3-4 days max.

Currently I only need a few minor parts that I will get locally at a NAPA store - tried both Pep Boys and Kragen because they were closer today but basically they are a joke for anything serious. I've read the manual for the VOControl computer I purchased from Plantdrive that I'll be using and it is a very sophisticated system with alot of options to tweak the system. I'll dive more into the setting once I get it up and running.

I've read the manual for the VOControl computer I purchased from Plantdrive that I'll be using and it is a very sophisticated system with alot of options to tweak the system. I'll dive more into the setting once I get it up and running.

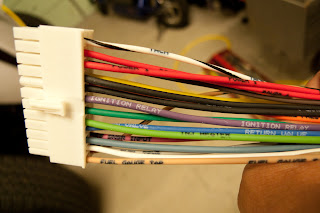

Other than finding the correct wires for the ignition "on" & "off" it looks pretty straight forward. Then again I've been down this road once before. The wiring harness (pictured above) is very cool because everything is labeled for it's purpose, this makes it alot easier to hook up.

The wiring harness (pictured above) is very cool because everything is labeled for it's purpose, this makes it alot easier to hook up.

The install will brake down into 3 distinct areas.

- plumbing

- fuel

- electric.

Before getting too far along there are a couple of things to re-remind anyone doing a conversion.

- We're assuming here that you have done all your research and are not entering this lightly. Only do the SVO thing if you drive long distances or will only switch to oil on the longer drives (this might be a challenge with a doughnut tank system, plus the thrill of driving for free). Short drives will not generate the heat required to get the oil to temperature. Depending on the ambient temperature and how you drive it could be 15 minutes before you can safely switch. ( ie: I drive 8 miles to work each way, mostly surface streets. This journey takes me about 20-25 minutes. I generally won't switch because by the time I have to purge I haven't used that much oil and I will only be removing diesel from a very small tank through the purging process. If you switch too early you will trash your engine.

- Do an oil analysis before you throw the switch. This gives you a baseline for the condition of your engine that you can compare other oil changes to down the road. This is important to have any idea if you are damaging your engine.

- Read Eg Beggs additional points to think about

Monday, May 11, 2009

When is a TDI's 190º really 150º

What I noticed immediately after installing one in my newly acquired 2002 TDI wagon was the discrepancy between the TDI's onboard water temperature gauge and the temperature the ScanGauge II was indicating. When the the TDI indicates 190º the SG2 shows 150º. The temperature will make it 190º+ but the initial 190º displayed on the dash is incorrect*. Now, to me this is very important if you have a manually controlled WVO system. My previous way of switching over to WVO was to wait until the water temp gauge of the TDI indicated 190º, then a would add an extra minute or two then throw the switch.

One can see the p

roblem here - if 160º is our intended temp. of the oil and the water that is heating the oil is only at 150, then it ain't gonna be at 160 at injection. Not to mention that these temp readings are w/o a WVO system installed so you have to figure it will take longer to reach temp because the cool oil is going to remove heat from the water as the oil is heated (heat sink).

roblem here - if 160º is our intended temp. of the oil and the water that is heating the oil is only at 150, then it ain't gonna be at 160 at injection. Not to mention that these temp readings are w/o a WVO system installed so you have to figure it will take longer to reach temp because the cool oil is going to remove heat from the water as the oil is heated (heat sink).Even if the coolant is at 150º, I figure that the engine is at normal operating temperature and the oil is being injected into a hot engine (injecting oil into an engine that is not at operating temp is a HUGE NO-NO. Getting the oil to 160º before injection helps reduce viscosity, reducing strain on the IP and provides a better spray pattern in the combution chamber.

With an automated system (computer controled such as Plantdrive's or Frybrid's) this all may be moot as the automated systems generally include their own temperature sensor for the engine's coolant. Thereby not switching over to oil until it's temp sensor indicates the coolant is at the predetermined temp.

Of course everything is also relative to the ambient temperature. If it's cool or cold outside the engine will be cooler also.

Of course everything is also relative to the ambient temperature. If it's cool or cold outside the engine will be cooler also.Here is a video on how to do a clean Scangauge install on a TDI

*I have noticed that the time it takes to get to engine's H20 to 190º is directly related to the intensity with which one drives. Drive mellow and it takes awhile and in some istances never makes it to 190 - settling around 185 or so. Drive agressively or get on the freway and it makes it to 190 and higher much quicker. This is important because if you switch over and the H2O never makes it to 190 your oil might not be at 160.

Sunday, March 08, 2009

Gone but not forgotten

From the start I wanted a TDI wagon but in 2006 when I started down the WVO road they were even more expensive than now. I also didn't want to spend a fortune on an "experiment" so I opted for the lesser expensive sedan.

From the start I wanted a TDI wagon but in 2006 when I started down the WVO road they were even more expensive than now. I also didn't want to spend a fortune on an "experiment" so I opted for the lesser expensive sedan.

There are two big reasons & one small one I recently purchased a wagon.

1.) It's better for work. In my line of business I sometimes need to bring some equipment with me.

2.) It's an automatic so my wife feels more comfortable driving it.

3.) All TDI wagons are made in Germany, my Jetta sedan, which runs great is made in Mexico.

So now that I am happy with the results I purchased a 2002 Jetta TDI I found on craigslist agragator foobert's TDI hunt. The car was outside Philly and I had it trucked to CA. In hindsight it was purchased at the worst time - gas prices where on their way down (it took a couple months to negotiate the price and work things out) and TDI's finally being let into California .

My initial plan was to sell the original kungpao jetta and drive the new wagon until the summer when I get my annual hiatus from work. That hasn't worked well, with gas becoming cheap and the kungpao not selling I decided to pull the VO kit off the car and try and sell it as a straight diesel. That didn't work either because as mentioned above the new clean diesels were entering the state and as I noticed on Craigslist a lot of sellers where selling their current TDI to get a new clean TDI. Then there's the economy and to be quite honest other than putting it in Craigslist a few times I haven't tried very hard to sell it because of my work schedule. I am going to start the process again and document it from the beginning as opposed to starting the blog afterward. It will be a slow initial process as I will only have the weekends until the end of April and I have other things in life that keep me busy.

I am going to start the process again and document it from the beginning as opposed to starting the blog afterward. It will be a slow initial process as I will only have the weekends until the end of April and I have other things in life that keep me busy.

Although it will be more Plantdrive specific the concept will be universal and the parts are easily exchangeable. I have the advantage of doing this once before.

Hopefully by the end it will be a good instuction manual for anyone looking for a how to and perhaps even a video out of it.